Article -> Article Details

| Title | Enhancing Control Systems with GE's Vibration Terminal Board |

|---|---|

| Category | Business --> Consumer Goods and Services |

| Meta Keywords | IS210DVIBH1B |

| Owner | World Of Controls |

| Description | |

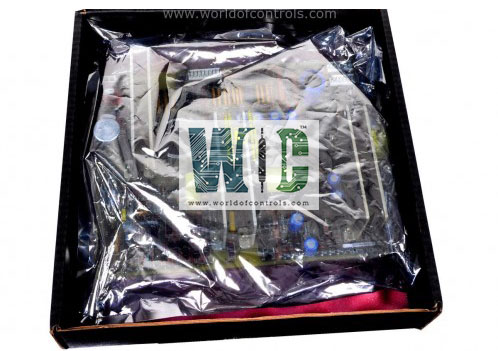

| In industrial automation, reliability and performance are paramount. One of the essential components that ensure efficient and accurate monitoring in control systems is the vibration terminal board. GE's advanced vibration terminal board is an integral part of the Mark VI control system, playing a crucial role in enhancing system functionality and performance. This article delves into the features, importance, and applications of the vibration terminal board, highlighting how it contributes to optimizing control systems. Overview of the Vibration Terminal BoardGE’s vibration terminal board is designed to provide effective monitoring and management of vibration signals in various industrial environments. It is specially engineered to work within the Mark VI control system, a widely used platform in power generation and industrial applications. The terminal board allows the integration of vibration sensors that detect oscillations in machinery and equipment, providing real-time data to the control system for further analysis and action.

Key Features and FunctionalityThe vibration terminal board boasts a range of features that enhance its performance and adaptability in different environments. Some of the key aspects include:

Importance in Control SystemsThe vibration terminal board significantly improves the reliability and efficiency of control systems. It provides operators with critical data that can be used to monitor the health of machinery and prevent unexpected failures. By detecting excessive vibrations, which often signal malfunction or wear, the board contributes to:

Applications in IndustryThe vibration terminal board has a broad range of applications in various industries, particularly in sectors that rely on large machinery and high-value equipment. These industries include:

ConclusionGE’s vibration terminal board plays an indispensable role in enhancing control systems by providing real-time data that ensures machinery health and operational safety. By offering features such as signal conditioning, diagnostic capabilities, and integration with the Mark VI control system, it helps industries optimize their processes, prevent equipment failures, and reduce maintenance costs. The board’s ability to detect early signs of failure makes it a valuable asset in predictive maintenance strategies, ultimately boosting the overall efficiency and reliability of control systems in industrial settings. | |