Article -> Article Details

| Title | Gasket Replacement in Plate and Frame Heat Exchangers |

|---|---|

| Category | Business --> Products |

| Meta Keywords | Plate and Frame Heat Exchangers |

| Owner | James Luther |

| Description | |

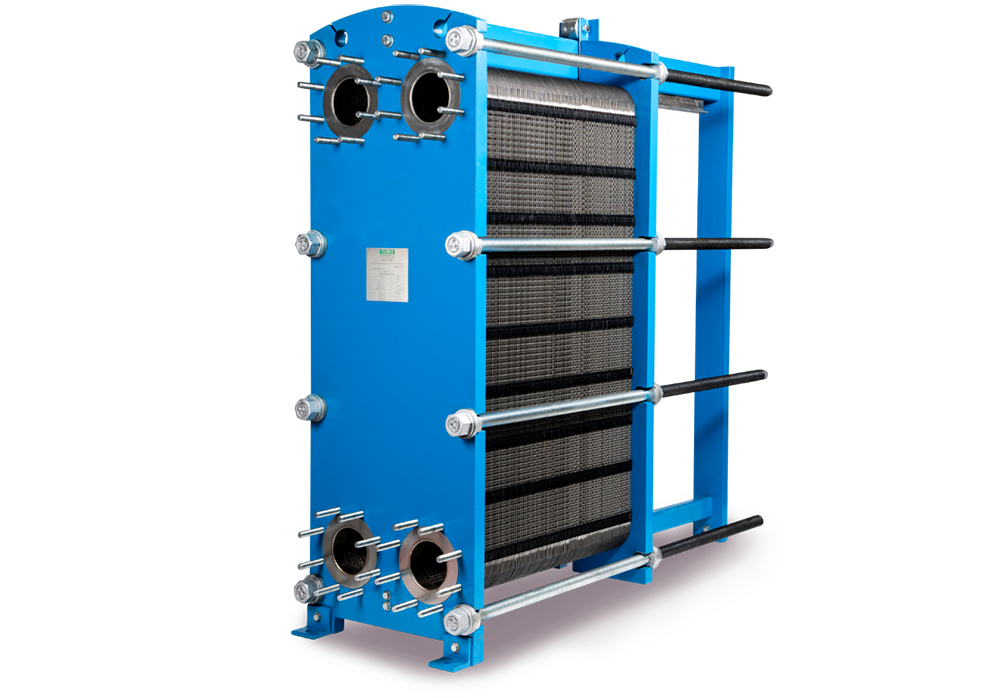

IntroductionAmong the numerous conservation tasks needed to keep artificial thermal systems running reliably, gasket relief in a plate and frame heat exchanger stands out as one of the most critical and most generally overlooked. Gaskets are the obscure icons of these systems. They seal the channels between plates, direct fluid inflow through the unit in the correct pattern, and help prevent cross-contamination between the hot and cold aqueducts. When gaskets fail, the consequences range from minor leaks to complete process shutdowns, product impurity, and indeed safety hazards. Understanding when and how to replace gaskets rightly is an essential skill for anyone responsible for maintaining plate and frame heat exchanger systems. The part of the Gaskets in a Plate and Frame Heat ExchangerTo appreciate why gasket conservation matters so much, it helps to understand exactly what gaskets do. In a plate and frame heat exchanger, each plate is framed by a perfection- moldered gasket that fits into a groove running around the plate's border. When the plate pack is clamped together within the frame, these gaskets compress to form a tight seal between conterminous plates, creating interspersing channels through which the hot and cold fluid aqueducts inflow without mixing. The gaskets also perform a secondary function they contain anchorages openings at the corners of each plate that are moreover sealed or open depending on the inflow arrangement. This picky sealing is what directs the fluids into their separate channels in the correct interspersing sequence. Without duly performing gaskets, this precise inflow distribution breaks down entirely. Given that gaskets are constantly subordinated to pressure, temperature cycling, and chemical exposure from the process fluids, their eventual declination is ineluctable. The question is n't whether they will need replacing, but when and whether you'll be ready when that time comes.

Signs That Gasket relief Is demandedCatching gasket failure beforehand can mean the difference between a planned conservation event and an unplanned exigency arrestment. There are several advising signs that indicate it's time to check or replace your gaskets. External Leaks The most egregious sign of gasket failure is fluid oohing from between the plates on the surface of the unit. Indeed a small drip should noway be ignored. What begins as a minor external leak can fleetly worsen as the gasket continues to deteriorate under operating conditions. Pressure Drop Increase A gradational rise in pressure drop across the heat exchanger can indicate that gaskets have begun to swell or distort, incompletely gumming the inflow channels. While fouling can beget analogous symptoms, a unforeseen or accelerating change in pressure drop clearances a full gasket examination. Thermal Performance Decline If outlet temperatures begin drifting down from their design values despite no changes in inflow rate or bay conditions, internal gasket leakage where fluid bypasses channels rather than following the correct inflow path may be the cause. Visible Damage on examination During any listed mechanical cleaning where the plate pack is disassembled, each gasket should be audited visually. Signs of hardening, cracking, swelling, extrusion from the groove, or endless contraction set all indicate that relief is necessary, indeed if no active leak has yet been observed. Choosing the Right Relief GasketsNot all gaskets are created equal, and opting the correct material for your specific operation is critical. The wrong gasket material can fail precociously, pollute the process fluid, or indeed reply chemically with it creating safety pitfalls in addition to conservation headaches. The most common gasket accoutrements include nitrile rubber (NBR), suitable for canvases , water, and numerous mild chemicals; ethylene propylene diene monomer( EPDM), preferred for hot water, brume, and numerous waterless results; neoprene, used in refrigerant and some chemical operations; and fluoroelastomers similar as Viton, which offer superior resistance to aggressive chemicals and high temperatures. Alwayscross-reference the gasket material against the full range of fluids, temperatures, pressures, and drawing chemicals the unit will be exposed to. When in mistrustfulness, consult the heat exchanger manufacturer or a good mastermind. Using an inharmonious material to save cost in the short term nearly always proves far more precious in the long run.

The Gasket Relief ProcessGasket relief should always be carried out in a clean, controlled terrain by trained labor force familiar with the specific outfit. The general process involves the following way. Begin by safely segregating the heat exchanger from the process closing insulation faucets, depressurizing the unit, and draining all residual fluid. Once the unit is safe to work on, loosen and remove the tensing bolts precipitously and unevenly to avoid distorting the frame or plates. Precisely separate the plate pack and lay the plates out in sequence so they can be reassembled in the correct order. Remove the old gaskets from each plate. Depending on the gasket attachment system fused, cropped, or snap- on this may bear a gasket junking tool or detergent to break down tenacious residue. Clean the gasket grooves completely before fitting the new gaskets, icing no debris remains that could help a proper seal. Fit the new gaskets, pressing them forcefully and unevenly into the groove around the entire plate.However, apply the correct glue in a livery, nonstop blob and allow the recommended curing time before reassembly, If fused gaskets are specified. Assemble the plate pack in the original sequence, also strain the frame bolts precipitously and unevenly to the manufacturer's specified necklace value noway overtighten, as this can damage both the plates and the new gaskets. Once reassembled, pressure- test the unit before returning it to service to confirm that all seals are complete. Why Kinetic Engineering Is the Right Partner for Your Heat Exchanger NeedsWhether you're planning a routine gasket relief or dealing with an unanticipated failure, having the right heat exchanger mate in your corner makes all the difference. Kinetic Engineering is a trusted name in perfection thermal operation, with deep moxie in heat exchanger design, conservation support, and the force of high- quality relief factors. Their educated engineering platoon understands that every operation is different, and they work nearly with guests to identify the right gasket accoutrements , plate specifications, and conservation strategies to maximize the trustability and lifetime of their outfit. From original outfit selection to long- term aftermarket support, Kinetic Engineering is committed to keeping your thermal systems performing at their stylish. ConclusionGasket relief is n't a task to be remitted or undervalued. In a plate and frame heat exchanger, gaskets are the critical interface between dependable performance and expensive failure. By learning to fete the early signs of gasket deterioration, opting the correct relief accoutrements for your specific process conditions, and following a chastened relief procedure, you can cover your outfit, maintain process effectiveness, and avoid the dislocations that come with unplanned time out. A visionary approach to gasket conservation is eventually an investment in the long- term health of your entire thermal system and with the right engineering mate by your side, it's an investment that pays tips every single day your factory is running. | |