Article -> Article Details

| Title | How Extraction Columns Enhance Chemical Separation? |

|---|---|

| Category | Web Directories --> Free |

| Meta Keywords | extraction columns |

| Owner | Kuber Precision Tech LLP |

| Description | |

| In the world of chemical engineering, extraction columns are crucial components used to separate chemical compounds in mixtures. These columns utilize the liquid-liquid extraction process to isolate specific substances, whether for refining, purifying, or concentrating a particular compound. Extraction columns are especially important in industries such as petrochemicals, pharmaceuticals, food processing, and environmental management, where precise separation is essential for product quality and efficiency. What Is an Extraction Column?An extraction column is a type of equipment used for separating compounds from a mixture based on their differences in solubility between two immiscible liquids. The liquid-liquid extraction column facilitates the contact between the liquid mixture and an extracting solvent, allowing components to be selectively transferred from one phase to another. The separation process typically occurs through repeated contact between the phases, allowing for multiple stages of extraction, which ultimately increases the purity of the extracted compounds. The Working Principle of Extraction ColumnsThe working principle of an extraction column revolves around liquid-liquid extraction, a separation technique based on differences in solubility. Here’s a step-by-step breakdown of how extraction columns work:

Types of Extraction ColumnsThere are several different types of extraction columns, each designed for specific applications and separation requirements. Below are some common types: 1. Packed ColumnA packed column is filled with packing material that provides surface area for mass transfer. This packing can be made from a variety of materials, including metal, ceramic, or plastic, and it helps to promote efficient contact between the two liquid phases.

2. Tray ColumnA tray column consists of multiple perforated trays or plates stacked on top of one another. Each tray provides a platform for vapor and liquid to come into contact, facilitating the extraction process.

3. Coiled or Spiral ColumnsIn coiled columns, the liquid flows through a spiral or helical path, providing additional surface area for the mass transfer process. These columns are typically used for processes where space is constrained.

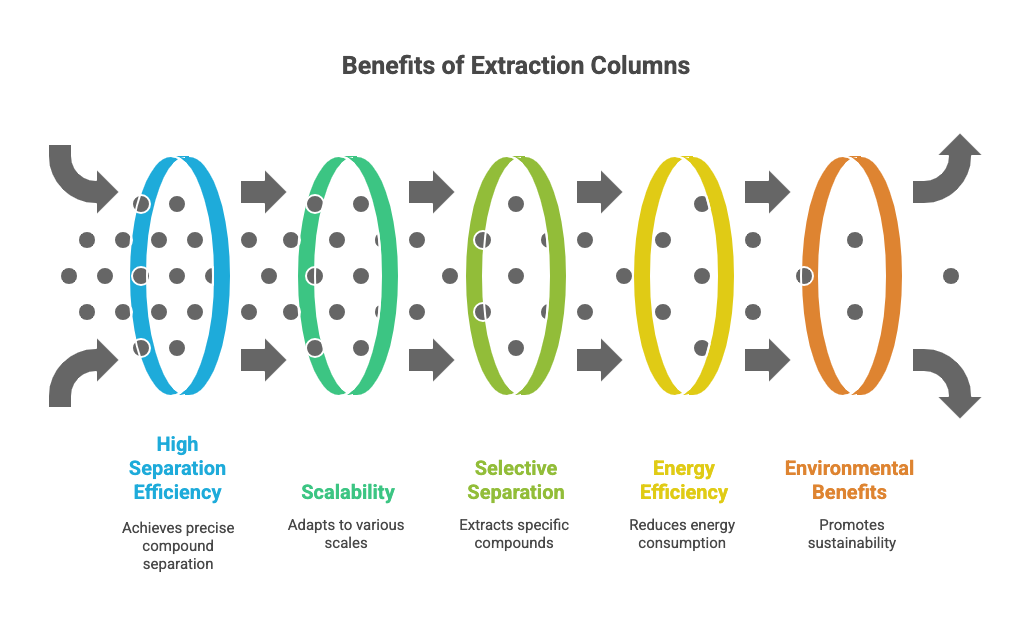

Benefits of Extraction Columns in Chemical SeparationExtraction columns play an essential role in improving the efficiency, selectivity, and sustainability of chemical separation processes. Here are the key benefits of using extraction columns in industrial settings: 1. High Separation EfficiencyOne of the primary advantages of using extraction columns is their ability to achieve high separation efficiency. By utilizing countercurrent flow and multiple stages of contact, extraction columns can separate chemical compounds with high precision, resulting in pure product recovery. 2. ScalabilityExtraction columns are scalable, meaning they can be designed for small-scale laboratory work or large-scale industrial processes. This flexibility makes them suitable for a wide range of applications across various industries, including chemical processing, pharmaceuticals, and food production. 3. Selective SeparationThe column extraction method enables selective separation of compounds based on their solubility. This selective transfer into the solvent phase is particularly useful in applications where only specific compounds need to be extracted, such as in fine chemical production or biochemical separations. 4. Energy EfficiencyCompared to other separation methods, such as distillation, extraction columns often require less energy, making them more cost-effective in the long run. The ability to recycle solvents further enhances the overall energy efficiency of the process. 5. Environmental BenefitsSince liquid-liquid extraction columns can be designed to use non-toxic or eco-friendly solvents, they are an environmentally sustainable choice. Additionally, the ability to recover solvents and re-use them reduces waste and chemical consumption.  Liquid-Liquid Extraction Columns: A Deeper DiveLiquid-liquid extraction columns are the most commonly used type in industrial separation. This method works by introducing an immiscible solvent into the column, where it contacts the feed liquid. Components with a higher solubility in the solvent phase will migrate into it, leaving the less soluble components in the original phase. Here’s why liquid-liquid extraction columns are so effective:

Applications of Extraction ColumnsExtraction columns are used in a wide range of industries, where efficient chemical separation is necessary:

ConclusionExtraction columns are indispensable for a variety of industrial processes that require precise chemical separation. Whether you’re involved in petrochemical refining, pharmaceutical manufacturing, or water treatment, extraction columns offer an efficient, scalable, and eco-friendly solution to achieve high-quality separations. | |