Article -> Article Details

| Title | Steel Rolling Mill: Backbone of Modern Steel Manufacturing |

|---|---|

| Category | Business --> Services |

| Meta Keywords | rolling mill |

| Owner | Mr. Dhanendra H. Rahangdale |

| Description | |

Introduction to Steel Rolling MillsA steel rolling mill is a vital facility in the manufacturing industry where raw steel billets or ingots are processed into usable steel products. Through a series of high-pressure rollers, steel is reshaped and resized to create beams, bars, rods, sheets, and structural components. From construction to automotive and heavy machinery, the steel rolling mill forms the bridge between steelmaking and industrial application.

What Happens in a Steel Rolling Mill?A steel rolling mill transforms semi-finished steel products (like billets or blooms) into finished goods using mechanical deformation techniques. This involves: 1. Reheating the SteelSteel billets are heated in a reheating furnace to approximately 1100°C–1300°C to make the metal ductile enough for rolling. 2. Rolling ProcessThe hot billet is passed through a series of rollers that reduce its thickness and shape it as per desired specifications. Depending on the application, this can be done via:

3. Cooling and FinishingAfter rolling, the steel is cooled using water or air, and then it's cut, coiled, or bundled before dispatch. Types of Steel Rolling Mills???? Hot Steel Rolling MillUsed for processing steel at high temperatures. Ideal for heavy industrial products like beams and rebars. ❄️ Cold Steel Rolling MillOperates at or near room temperature. Suitable for steel sheets, automotive components, and appliances. ???? Reversible Rolling MillAllows steel to pass back and forth between rolls, increasing production flexibility. ????️ Tandem Rolling MillMultiple rolling mills work in series for high-speed and high-volume production, common in steel strip manufacturing. Machinery Used in Steel Rolling MillsEfficient production depends on specialized machinery. Key components include:

Keyword Tip: These are commonly searched with queries like “rolling mill equipment”, “hot rolling machinery”, and “steel rolling plant setup”.

Applications of Steel Rolled in Rolling Mills

Importance of Steel Rolling Mills in the Industry

Challenges in Steel Rolling Mill OperationsEven with automation, rolling mills face operational difficulties such as:

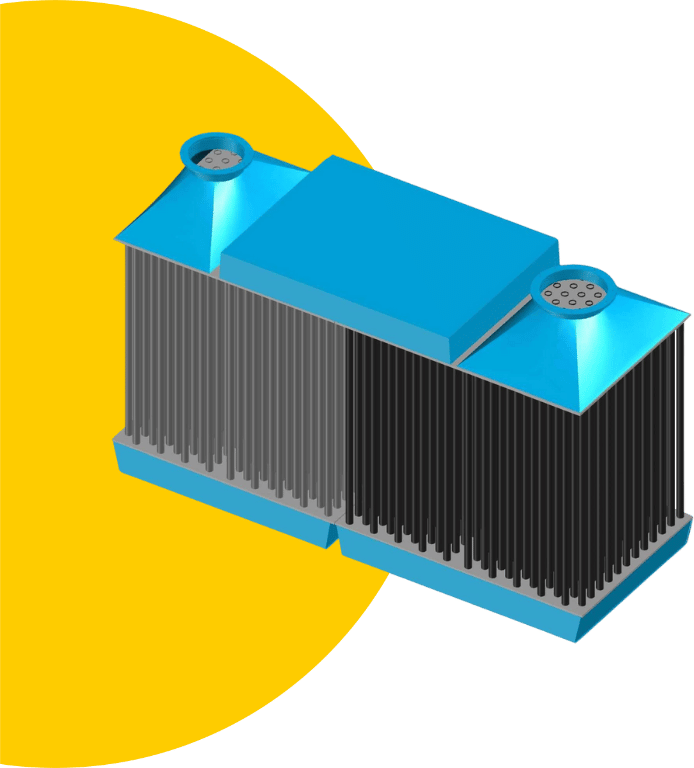

The Role of Reheating Furnaces in Steel Rolling MillsA high-performance reheating furnace is the foundation of a smooth rolling operation. It ensures:

Why Trymax Furnace Pvt. Ltd.?As one of the top furnace manufacturers in India, Trymax specializes in custom reheating solutions tailored for steel rolling mills. With advanced design, automation, and heat control features, our furnaces optimize rolling productivity and reduce energy costs. Trends in the Steel Rolling Mill Industry

ConclusionA steel rolling mill is more than just a piece of industrial machinery—it's a cornerstone of the steel production ecosystem. With growing demand for high-quality steel products, investing in the right rolling mill setup and advanced reheating furnaces is essential. Companies like Trymax Furnace Pvt. Ltd. not only manufacture world-class reheating furnaces but also contribute to the evolution of smarter and more efficient rolling mill operations. Whether you're a steel producer, investor, or industrial consultant, understanding the steel rolling mill process is key to unlocking growth and efficiency in the metal industry. | |