Article -> Article Details

| Title | Why Dynamic Pressure Terminal Boards Are Critical for Real-Time Monitoring |

|---|---|

| Category | Business --> Consumer Goods and Services |

| Meta Keywords | IS210DDPTH1AA |

| Owner | World Of Controls |

| Description | |

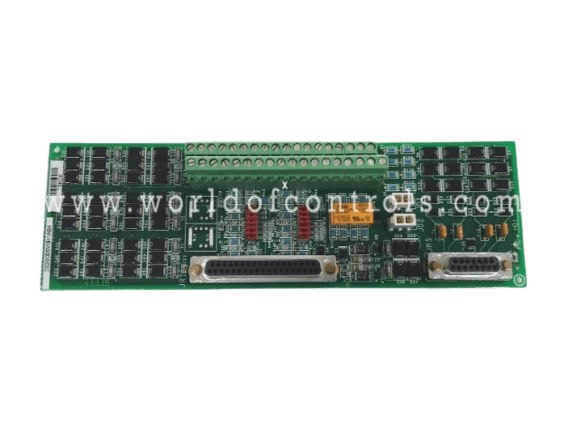

| In the world of high-performance machinery—particularly in power generation and gas turbines—real-time monitoring of dynamic conditions is essential. Among the most critical of these parameters is dynamic pressure, which directly impacts the efficiency, stability, and safety of turbine operations. This is where dynamic pressure terminal boards play a vital role. These specialized interface devices bridge the gap between dynamic pressure sensors and turbine control systems, ensuring precise and timely data capture.

What Is Dynamic Pressure and Why Monitor It?Dynamic pressure refers to the component of pressure related to the motion of a fluid—typically air or combustion gases. It fluctuates in real-time, especially in fast-changing environments like turbine combustors or exhaust flows. Monitoring dynamic pressure is crucial because:

In gas turbines, where even minor fluctuations can signal performance issues or safety hazards, accurate monitoring of dynamic pressure is fundamental. The Role of Terminal Boards in Monitoring SystemsDynamic pressure terminal boards are hardware modules that connect pressure transducers (sensors) to the turbine's control system. These boards are designed to:

By ensuring that data from sensors is clean, timely, and accurately mapped, these boards enable turbines to respond to dynamic changes with high reliability. Application in Turbine Control SystemsIn modern gas and steam turbines, dynamic pressure monitoring is often integrated into broader automated control architectures. Terminal boards are mounted within control panels or enclosures and act as intermediaries between the physical sensing environment and the software-based control logic. Their typical applications include:

Without terminal boards, these vital measurements would either be delayed, distorted, or lost altogether, weakening the control system’s responsiveness. Benefits of Using Dynamic Pressure Terminal Boards1. Accurate Real-Time DataTerminal boards ensure that pressure readings reflect the real-world environment with minimal latency or distortion. This precision allows turbine systems to operate at optimal efficiency while minimizing risks. 2. Robust Signal HandlingHigh-frequency pressure signals can be sensitive to interference. Terminal boards provide filtering, shielding, and grounding pathways that maintain signal integrity in electrically noisy environments. 3. System IntegrationThese boards are designed to integrate seamlessly with turbine control platforms—such as digital control systems used in industrial automation. This makes it easier for operators to incorporate real-time data into dashboards, safety systems, and historical logs. 4. Support for Predictive MaintenanceBy continuously tracking dynamic pressure trends, terminal boards help enable predictive diagnostics. Anomalies can be identified early, allowing maintenance to be scheduled before issues escalate. Beyond Turbines: Broader Industrial UseWhile especially critical in turbine applications, dynamic pressure terminal boards are also used in:

Any system dealing with fast, high-pressure fluid flows can benefit from dynamic pressure monitoring, and thus, from terminal boards that ensure data quality and speed. ConclusionDynamic pressure terminal boards are silent enablers of real-time, high-accuracy monitoring in complex mechanical systems. In gas turbine operations, their importance cannot be overstated—they are essential for maintaining performance, preventing failures, and enabling smarter maintenance strategies. As turbine systems become more intelligent and data-driven, terminal boards will continue to play a foundational role in making real-time monitoring both possible and dependable. More Products | |